Home > Material Reporting > Strengthening Product Reliability and Safety

Enhancing reliability test competency

Reinforcement of Failure Prediction & Analysis Capabilities

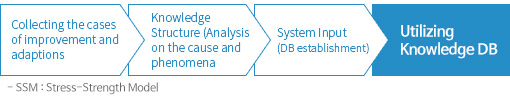

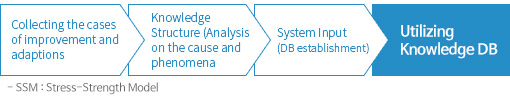

Coway improves the completeness of the product design by implementing the process of functional failure prediction and cause analysis, and enhances the reliability of the products by preventing the defects and failures of the products.

DFMEA Process

SSM system

FRACAS Process

Re-verifying the Effectiveness of Accelerated Life Test Methods

The accelerated life test is the process of testing a product by subjecting it to conditions (stress) in excess of its normal service parameters to estimate the life expectancy of a product. Coway has continuously made use of an accelerated life-testing system since 2009, and secured the standards to strengthen product durability in 2014 by re-verifying the effectiveness of these very same test methods.

Coway has expanded Wi-Fi, NFC wireless technology measuring equipment for wireless network verification, and established the equipment for IAQ(Indoor Air Quality) sensing technology measurement such CO2 sensor, dirt sensor etc. In addition, the verification system in mobile app for controlling the product and collecting information has been established so that the customers can use the products in a more convenient way.

In 2016, new verification schemes including blue-tooth, zigbee etc., in responding to a variety of wireless communication technologies will be developed, and the upgrades for measurement facilities and equipment continue to be in process. Coway also plans to strengthen the capacity to accommodate a variety of product development utilizing IoT related technologies in the future by securing the verification capacity for new censors.

Strengthening overseas field test

Coway conducts a domestic and overseas field tests to overcome the limitations of the test and evaluation performed in the restrictive environments of test labs and to evaluate the suitability and robust design of the product in the actual use environment and from the customers’ points of view. The evaluation proceeds from the customer standpoint including the design, UI, performance and emotional part of the product and the test results are reflected immediately on the product design to complete the final product.

In 2015, the international field test procedure was improved to make the field test tasks achieved organically and smoothly from field test pre-checking, selection of target people, product delivery to local adaption. In particular, field tests were conducted in countries such as the US, China, Japan, Malaysia, and Australia etc., so that the local customers’ opinions could be reflected on the product design, and the user environmental conditions such as water quality and pressure were investigated and knowledge based so that they can be utilized continuously in the course of developing the products for international markets in the future.

Establishing & Amending Reliability Test Methods

In an effort to secure product reliability testing capabilities that meet the most stringent global standards, Coway established a reliability test methods after examining examples of six advanced companies in Korea and abroad, international standards (IEC, ISO), national standards (KS, MIL, JIS, BS), those of related organizations (JEDEC, EIAJ), and Coway’s own standards. Since then, the company has continually reflected failure cases and test methods from the customers’ point of view every year, and as of 2015 claimed the rights to 251 reliability test method cases as intellectual properties.

Establishing & Amending Reliability Test Methods

| year |

Establishment |

Amendment |

|

2009

|

115 |

0 |

|

2010

|

27 |

28 |

|

2011

|

17 |

17 |

|

2012

|

22 |

14 |

|

2013

|

22 |

29 |

|

2014

|

26 |

24 |

|

2015

|

26 |

15 |

Enhanced capabilities of testing personnel

Coway enhances the capabilities of testing personnel by self-learning and collaborations with external organizations. R-campus has been developed as a reliability professional education program to select the required training items according to the test fields and the positions, which leads to systematically foster the reliability professionals through individual education goals design and education history checks based on this program. Externally, Coway has signed the agreement of national Human Resource Development Consortium with the Ministry of Labor and provides more professional training opportunities for the testing personnel through a step-by-step training system. In addition, Coway supports training for and obtaining the international qualifications such as CRE (Certified Reliability Engineer), CPLP (ISTA Certified Packaging Laboratory Professional), iNARTE (International EMC engineer certification) etc. Moreover, Coway has been sharing the latest issues and trends, best practices etc., by holding the regular reliability technology seminars.