Natural Resources Used in Business Activities

Use of Materials

| Category |

2012 |

2013 |

2014 |

2015 |

Notes |

Non Renewable Raw Materials

(Unit: tons) |

Plastics |

8,988 |

7,482 |

8,724 |

9,185 |

Filters, 5 major products (1) |

| Metal |

4,867 |

3,664 |

4,056 |

4,332 |

Theoretical weight applied |

| Theoretical weight applied (2) |

2,000 |

1,922 |

1,983 |

2,266 |

|

| Renewable Raw Materials |

- |

- |

- |

- |

- |

|

| Total (Unit: tons) |

15,855 |

13,068 |

14,763 |

15,783 |

|

|

(1) Water filtration systems, air purifiers, bidets, water softeners.

And food waste treatment appliances

(2) Packaging materials: paper boxes, plastics & protective films, and use of EPS in 2015

Water Use

According to features of manufacturing facility that operates the process around assembly-oriented, so the company’s environmental impact on water resources through its water use or the discharge of waste water is not significant. Still, Coway is adamant about reducing its water use. One way it has done this is by developing a “waterless” water purifier test system that uses nitrogen and vacuum conditions instead of water. Additionally, Coway was the first Korean company to become a signatory of the UNGC CEO Water Mandate, and has done its best to protect water resources throughout the production process.

| Category |

2013 |

2014 |

2015 |

| Yugu Plant |

20,832 |

31,221 |

30,916 |

| Incheon Plant |

13,443 |

12,151 |

16,603 |

| Pocheon Plant |

392 |

340 |

235 |

| Environmental Technology Institute (R&D Center) |

27,770 |

19,995 |

15,104 |

| Logistics Center (Yugu) |

1,644 |

2,340 |

3,386 |

| Total (Unit: tons) |

64,101 |

66,047 |

66,244 |

Energy Use

In order to increase the efficiency of energy use, Coway installed photovoltaic generators at its production facilities and is expanding its use of renewable energy. The company also joined the Win-Win Energy Companion project, and offered energy quantification equipment to reinforce suppliers’ energy competitiveness.

| Category |

Energy Source |

2013 |

2014 |

2015 |

| Direct |

Butane(GJ) |

20 |

7 |

2 |

| LPG(GJ) |

40 |

44 |

- |

| Diesel(GJ) |

270 |

250 |

268 |

| LNG(GJ) |

2,164 |

1,567 |

1,601 |

| Kerosene(GJ) |

611 |

209 |

267 |

| Propane(GJ) |

1,078 |

1,135 |

4,126 |

| Direct Total(GJ) |

|

4,183 |

3,212 |

6,264 |

| Indirect |

Electricity(GJ) |

104,022 |

103,944 |

103,640 |

| Indirect Total(GJ) |

|

104,022 |

103,944 |

103,640 |

| Total(GJ) |

|

108,205 |

107,155 |

109,903 |

- JoongAng Ilbo Building(Seoul Office), Seoul National University Environmental Technology Research Center, Cosmetics Research Center, Water Treatment Project Office, Yugu Distribution Center, Manufacturing Factories(Yugu, Incheon, Pocheon)

- Classified LPG to propane according to the verification of greenhouse gas goal control system criteria

|

| Energy Use per Unit(GJ/KRW 100 million) |

5.60 |

5.32 |

5.08 |

|

Total energy use(GJ)/Total sales(KRW 100 million)

|

| Adoption of

Renewable Energy |

Photovoltaic facility installation costs(KRW 100 million) |

1.1 |

2.0 |

1.7 |

| Reduction in power

consumption(kw)(1) |

18,998 |

71,528 |

189,457 |

- 2013-Pocheon plant

- 2014-Yugu plant, one supplier

- 2015-Incheon Plant, one supplier

|

(1) The 2013 data represents the total amount of power saved from

the operation of a photovoltaic generator at the pocheon plant. this is based on separate financial statements.

Environmental Impact due to Business Activities

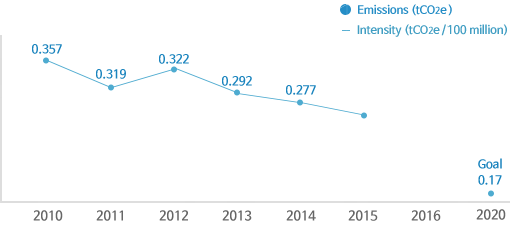

GHG Emissions

Coway is the only Korean company which declared its support for the ‘UN Framework Convention on Climate Change’ agreed by 195 countries at the COP21 held in Paris in December 2015 and has been participating in the corporate voluntary carbon reduction plan scheme. Coway plans to reduce the GHG emission per unit by 50% of the year 2010 by the year 2020 in order to accomplish the mid & long term reduction goal of greenhouse gas established in 2009. Accordingly, Coway has developed the energy saving activity participated in together by staff & employees and partners to minimize the greenhouse gas emission at all manufacturing and sales fields.

| Category (Unit: tCO₂e ) |

2013 |

2014 |

2015 |

| Direct Emissions (Scope1) |

256 |

196 |

391 |

| Indirect Emissions (Scope2) |

5,389 |

5,385 |

5,369 |

| Indirect Emissions (Scope1+2) |

5,645 |

5,581 |

5,760 |

| Yugu Plant |

1,695 |

1,919 |

2,015 |

| Incheon Plant |

695 |

634 |

658 |

| Pocheon Plant |

394 |

361 |

349 |

| Environmental Technology Institute (R&D Center) |

1,628 |

1,537 |

1,565 |

| Cosmetics Research Institute |

180 |

163 |

174 |

| Seoul Office (JoongAng Dail yBuilding) |

384 |

399 |

390 |

| Logistics Center (Yugu) |

499 |

413 |

464 |

| Water Environment Business Division |

169 |

154 |

145 |

| Net Emissions(CO₂e/KRW100) |

0.292 |

0.277 |

0.266 |

| Domestic Logistics and Transport (Scope 3) |

3,156 |

4,025 |

4,514 |

| Commuting Vehicles (Scope 3) |

49 |

49 |

49 |

- Domestic logistics and transport are carried out through subcontracts, which are excluded from the company’s calculation of emissions (data is taken from subcontractors).

- The direct emissions 391 tCO₂e is the value that the error of propane volume → weight conversion process is corrected, and the value prior to the correction is 191 tCO₂e. Therefore, when compared with 2014 it is 5,560 tCO₂e, reduced by 21 tCO₂e.

GHG Emissions from the Use of Refrigerants

| Category |

R-134a |

R-12 |

| 2013 |

2014 |

2015 |

2013 |

2014 |

2015 |

| Use of Refrigerants in Product Manufacturing (kg) |

14,823 |

43,867 |

50,238 |

122 |

- |

- |

| Use of Refrigerants in Product Disposal (Kg) |

12,725 |

13,558 |

15,562 |

4,580 |

3,061 |

2,066 |

| GHG Emissions Caused by Refrigerants from Waste Products (tCO₂e) |

13,234 |

14,073 |

16,185 |

39,937 |

26,640 |

18,016 |

Status of Mid & Long Term Accomplishment in Reduction Goal of GHG Emissions

Generation of Waste

| Category |

|

2013 |

2014 |

2015 |

| Generation of Waste |

Products |

11,765 |

12,808 |

13,263 |

| Business Site: General |

1,003 |

1,028 |

1,023 |

| Business Site: Designated |

25 |

26 |

27 |

| Services |

6,772 |

7,024 |

8,501 |

| Total (Unit: tons) |

|

19,565 |

20,886 |

22,814 |

| Amount of Waste Recycled (Unit: tons) |

|

11,817 |

12,228 |

12,837 |

| Waste Recycling Rate (%) |

|

60 |

59 |

56 |

Plastics Recycling

Coway has expanded its management scope from the manufacturing and distribution of products to waste that occurs during its service process, as CODYs recollect waste filters after carrying out their services, thus enabling waste separation.

| Category |

2013 |

2014 |

2015 |

Notes |

| Output (tons) |

7,482 |

8,724 |

9,185 |

Amount of plastics used in products on the market (filters, 5 major products) |

| Amount Recycled (tons) |

5,638 |

6,198 |

6,353 |

Sales amount of recollected and recycled products |

| Recycling Rate (%) |

75.4 |

71.1 |

69 |

(Amount of recycled plastics/Plastics output) X 100 |

- Products: filters, air / water purifiers, bidets, water softeners, food wast processors

- Recycle Rate: (waste product / filter) plastic recycle rate / product/filter) plastic delivery Amount

- Waste product / filter return and recycling qty increase continuously. However, the increase range of product shipping is high so that its recycling rate decreases.

Discharge of Other Pollutants

Coway operates an assembly-oriented production process in which more than

95 percent of total energy use is electric energy. There are no air pollutants or

wastewater during the process, and Coway does not separately measure/manage

fossil energy for heating offices and travelling. The same applies to water usage, in

which Coway does not evaluate the contamination of sewage water separately.

Sales of Refurbished Products

For customers who purchase new products and dispose of existing ones, Coway collects the used products free of charge. The recollected products are handled at the company’s Recycling Center, where plastics are recycled, some of which are later sold as refurbished products. In 2013, Coway signed an MOU with the Ministry of Environment and the Korean Environment Corporation on this very issue and has been working hard to facilitate the sale of refurbished products since then.

| Category(Unit: No. of units) |

2013 |

2014 |

2015 |

| Water Filtration Appliances |

15,571 |

12,061 |

13,492 |

| Air Purifiers |

4,959 |

2,672 |

4,508 |

| Water Softeners |

597 |

366 |

49 |

| Bidets |

6,850 |

3,454 |

3,486 |

| Food Waste Treatment Appliances |

146 |

30 |

- |

| Total |

28,123 |

18,583 |

21,535 |

Activities to Reduce Coway’s Environmental Impact

Environmental Investments

| Category (Unit: KRW million) |

2013 |

2014 |

2015 |

| Facility Operations |

1,125.8 |

186.5 |

71.3 |

| System Operations |

75.3 |

66.5 |

119.85 |

| Communication |

915.8 |

616.0 |

373.7 |

| New Environmental Businesses |

- |

59.0 |

149.2 |

| Total |

2,116.9 |

928.0 |

714 |

- Environmental investments do not include investments made to improve products and service quality.

Eco-friendly Product

| Category (Unit: KRW 100 million) |

2013 |

2014 |

2015 |

| Sales |

5,000 |

6,034 |

5,972 |

Hazardous Substance Process Management

Coway operates a hazardous substance process management system to minimize the amount of hazardous substances contained in its products.Since 2006, The company has responded to environmental regulations such as EU RoHS and WEEE for exports to Europe, and is responding to Korea’s Act on the Resource Circulation of Electrical and Electronic Equipment and Vehicles ever since Coway

products fell under the terms of the law in 2014.

| Category (Unit: %) |

2013 |

2014 |

2015 |

| Response Rate to Parts Containing Hazardous Substances |

95.5 |

100 |

100 |

Reducing Suppliers’ Environmental Impact

Green Partnerships

Coway’s Green Partnership (GP) certification system helps Coway to produce

eco-friendly products and offers Green Partner certificates for suppliers that

meet Coway’s stringent environmental & quality management standards.

| Category |

2013 |

2014 |

2015 |

| Suppliers Certified with Coway’s Green Partnership Certificate |

55 |

55 |

55 |

Suppliers’ GHG Emissions

Coway continuously supports carbon partnership suppliers and reinforces their

competitiveness by encouraging them to reduce energy use in relation to sales

growth. In doing so, Coway is successfully reducing suppliers’ environmental

risks due to climate change.

| Category |

2013 |

2014 |

2015 |

| Category(tCO₂e) |

47,806 |

44,445 |

36,181 |

| Emissions per Unit(tCO₂e/KRW 100 million) |

12.48 |

10.56 |

8.46 |

※ Based on 26 major carbon partnership suppliers.

Support for Carbon Partnerships

Coway has selected 26 suppliers that deliver major raw materials in large trade amounts and energy use, and now maintains carbon partnerships with them. Every year, the company measures these key suppliers’ GHG emissions and emissions per unit, reinforcing their response capabilities to climate change.

| Category |

Period |

Major Description |

| Win-Win Energy Partnership |

Jun. - Oct. 2015 |

Diagnosis of energy issues at business sites (Encourage investment) |

| Support for Suppliers Adopting Renewable Energy Sources |

May. - Jul. 2015 |

Offering 0 percent interest financial support for 2 years when suppliers join a photovoltaic building project |